Digital Twin Simulations

Welcome to our Digital Twin Simulation solutions—where virtual innovation meets real-world efficiency. As a trusted provider of advanced digital twin technology, we harness cutting-edge simulation and real-time analytics to create dynamic virtual replicas of your systems. Our tailored approach transforms your operations into a proactive, data-driven environment, enabling predictive insights, optimized performance, and a competitive edge in today's fast-paced market.

Applications and Use Cases

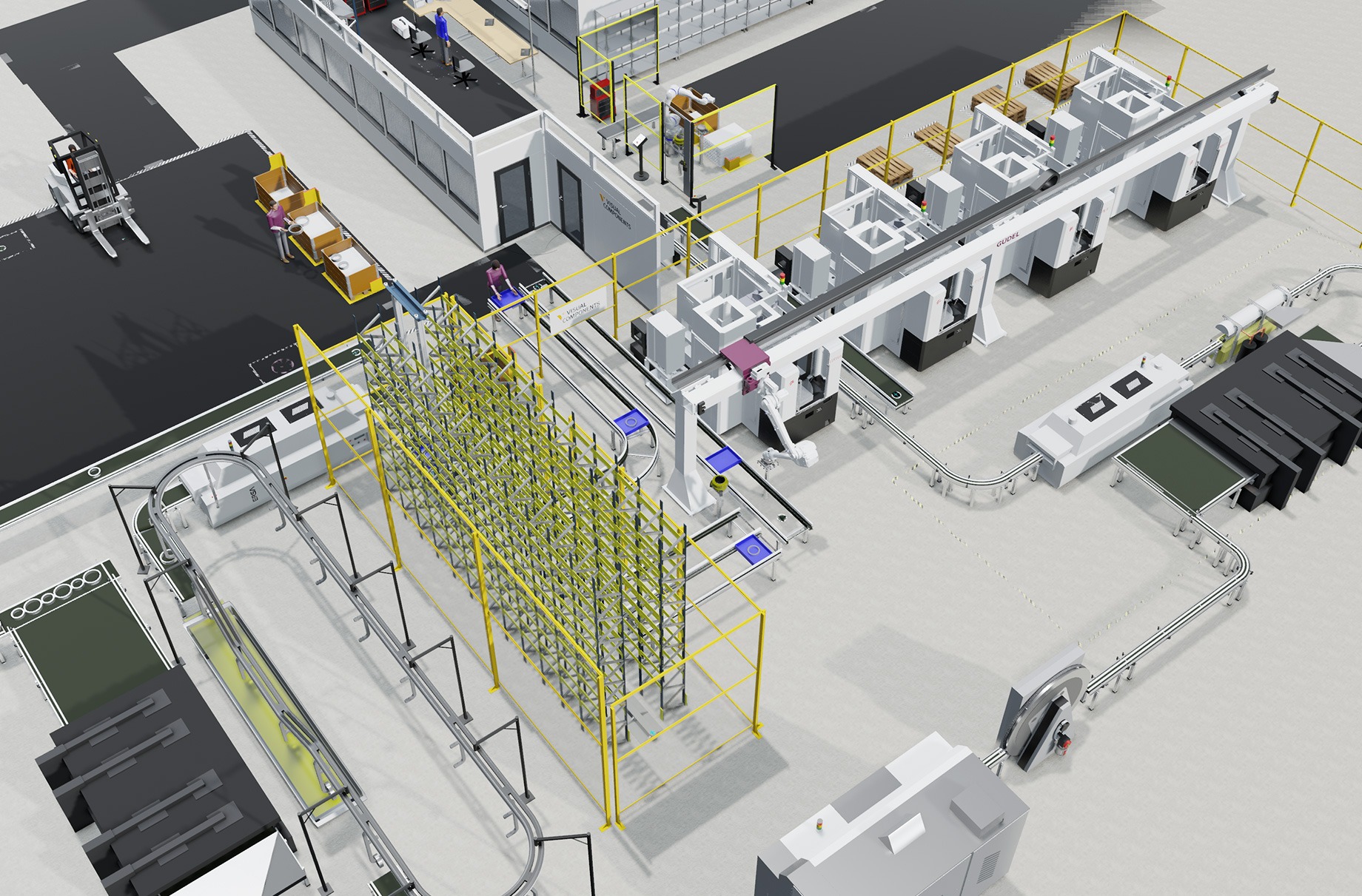

This digital twin simulation service provides a real-time virtual replica of manufacturing processes, enabling predictive maintenance, process optimization, and enhanced decision-making. It integrates sensor data and advanced analytics to create a dynamic simulation environment, helping manufacturers reduce downtime and improve efficiency.

Advanced Digital Twin Simulation

This digital twin simulation service provides a real-time virtual replica of manufacturing processes, enabling predictive maintenance, process optimization, and enhanced decision-making. It integrates sensor data and advanced analytics to create a dynamic simulation environment, helping manufacturers reduce downtime and improve efficiency.

This service creates a digital replica of production lines to simulate and test new equipment or process changes before physical implementation. It reduces commissioning time and enhances system reliability.

Virtual Commissioning & Testing

This service creates a digital replica of production lines to simulate and test new equipment or process changes before physical implementation. It reduces commissioning time and enhances system reliability.

Leveraging real-time data and historical trends, this service models various operational scenarios to predict potential outcomes. It assists in risk assessment and strategic planning.

Predictive Scenario Modeling

Leveraging real-time data and historical trends, this service models various operational scenarios to predict potential outcomes. It assists in risk assessment and strategic planning.

This digital twin service simulates entire production processes to identify bottlenecks and optimize workflows. It provides actionable insights for continuous improvement.

Process Optimization Simulation

This digital twin service simulates entire production processes to identify bottlenecks and optimize workflows. It provides actionable insights for continuous improvement.

This solution benchmarks real-time production performance against digital twin simulations, identifying discrepancies and opportunities for improvement.

Real-Time Performance Benchmarking

This solution benchmarks real-time production performance against digital twin simulations, identifying discrepancies and opportunities for improvement.

This service leverages digital twin technology to optimize facility layout and design. It simulates material flow and spatial organization to maximize operational efficiency.

Design & Layout Optimization

This service leverages digital twin technology to optimize facility layout and design. It simulates material flow and spatial organization to maximize operational efficiency.

This digital twin simulation provides immersive training environments for operators, allowing them to practice on virtual replicas of machinery and production lines before working on real equipment.

Virtual Operator Training

This digital twin simulation provides immersive training environments for operators, allowing them to practice on virtual replicas of machinery and production lines before working on real equipment.

By creating a digital replica of the supply chain, this service enhances transparency and efficiency. It simulates logistics scenarios to optimize inventory and delivery schedules.

Supply Chain Digital Twin

By creating a digital replica of the supply chain, this service enhances transparency and efficiency. It simulates logistics scenarios to optimize inventory and delivery schedules.

This solution simulates process changes and re-engineering efforts to evaluate their impact before implementation. It helps businesses refine workflows with minimal disruption.

Virtual Process Re-engineering

This solution simulates process changes and re-engineering efforts to evaluate their impact before implementation. It helps businesses refine workflows with minimal disruption.

Integrating real-time sensor data into digital twin models, this service provides up-to-date simulations for accurate decision-making. It bridges the gap between virtual and physical operations.

Real-Time Data Integration

Integrating real-time sensor data into digital twin models, this service provides up-to-date simulations for accurate decision-making. It bridges the gap between virtual and physical operations.

This comprehensive service creates digital twins for entire product lifecycles, from design to disposal. It supports sustainable practices and product innovation through continuous simulation.

Digital Twin for Product Lifecycle Management

This comprehensive service creates digital twins for entire product lifecycles, from design to disposal. It supports sustainable practices and product innovation through continuous simulation.

Our Partner

Visual Components is a leading developer of 3D manufacturing simulation and robot offline programming (OLP) software. Founded in 1999 by a team of simulation experts in Helsinki, Finland, the company set out to make manufacturing design and simulation technology easy to use and accessible to organizations of all sizes.

Over the past 25 years, Visual Components has introduced several innovations, including its 3D product family and a next-generation OLP software. The company's expertise in simulation, automation, and Industry 4.0 has positioned it at the forefront of manufacturing simulation technology.