Robotic Arm Solutions

50+

Happy Clients

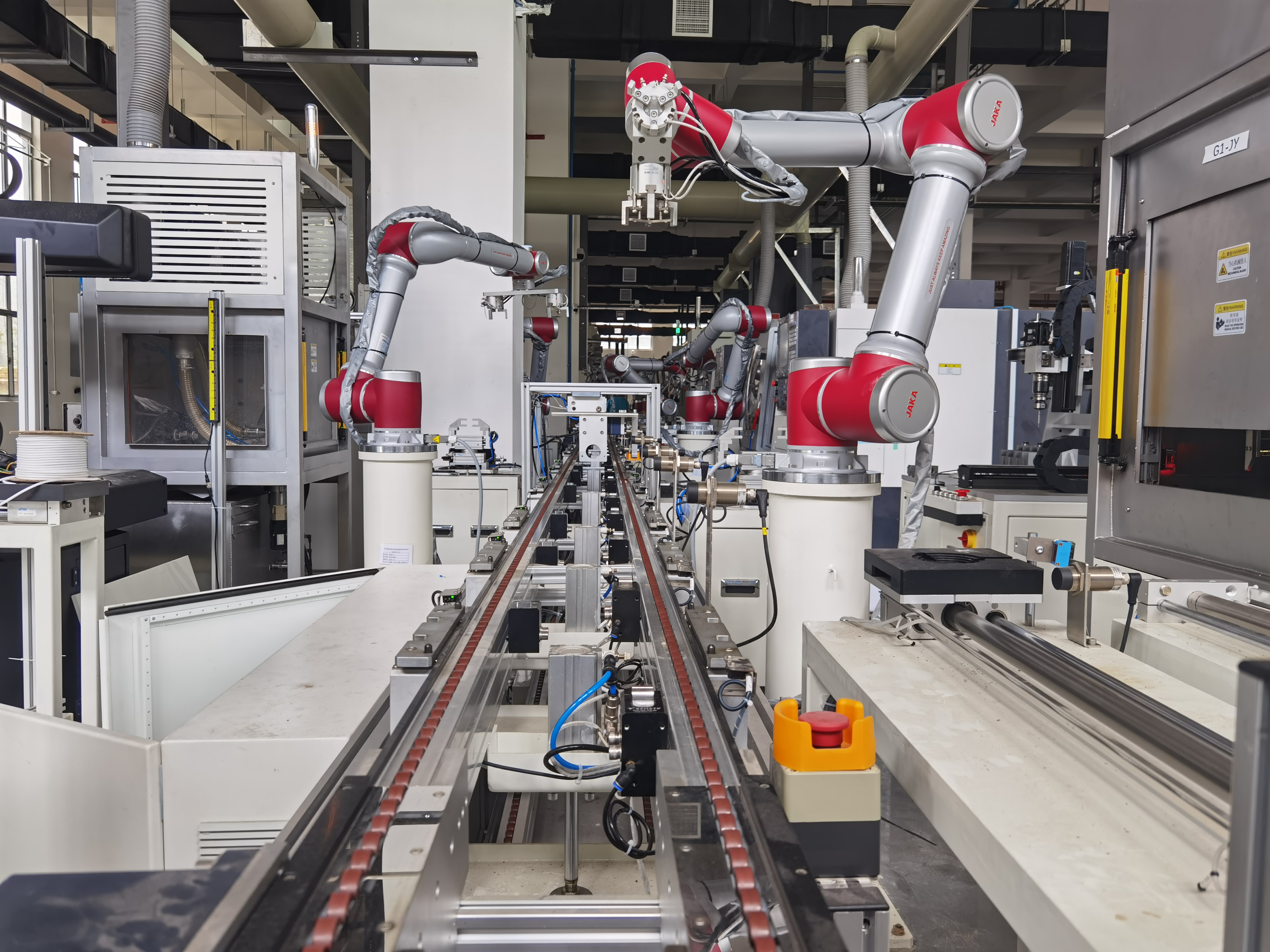

Robotic Arm Automation

Welcome to our Robotic Arm solutions—where precision meets automation. As a trusted provider of advanced robotic arms, we integrate cutting-edge technology with your operations to boost efficiency and accuracy. Our tailored approach transforms your facility into a high-performance, data-driven environment, ensuring enhanced production quality, increased safety, and a competitive edge in today's fast-paced market.

Use Cases

Machine Tending

Cobots take over repetitive tasks like loading and unloading machines, reducing manual labor. They work continuously with precision to keep production equipment operating at peak efficiency. This automation not only boosts productivity but also enhances overall workplace safety.